10 Ways to Address Energy Use in Science+Technology Facilities

1. Shut the Sash

Fume hoods are one of the most energy-intensive pieces of equipment in a lab, but significant savings can be achieved by keeping them closed when not in use. Consider implementing a “Shut the Sash” awareness program that rewards groups who most consistently shut sashes when not in use. The practice can save up to $2,000 annually per hood, and will keep your occupants safe.

2. Save Money on Lighting

Eliminating lighting in spaces that don’t need full lighting levels can save money. Reducing the light levels in corridors is a good first step. Within the labs, reducing ambient lighting to 50 foot-candles at the bench, and using more efficient LED task lighting where additional light is needed should provide sufficient light levels for most scientific activities. Finally, while it may seem like a no-brainer, prioritize developing a culture where the last one out always turns off the lights.

3. Start a Freezer Management Program

In addition to being noisy, ultralow temperature freezers use a lot of electricity and release heat into the space they occupy. Installing these freezers in central areas reduces the impact on the mechanical systems servicing your labs. Most long-term freezer samples can be stored at -70° C instead of the standard -80°C. This temperature tuning of your freezers a mere 10° will conserve up to 40% more energy. Once you have raised your freezer temperature, there are several other maintenance items that can improve freezer energy consumption: – Defrost freezers regularly to maintain optimal energy use and storage capacity – Keep filters and fins clean – Discard samples that are no longer in use – Once the units have outlived their useful life, purchase replacement units that are energy-efficient and use scroll compressors.

4. Conserve Purified Water

It takes 2 to 3 units of water to make 1 unit of purified water. Many researchers don’t like the automatic shut-off valves we suggest for the pure water fixtures, but with the high cost of producing and supplying pure water to the lab, it is important to only use what you need, and utilizing these valves is a great way to cut down on waste.

5. Green Purchasing & Recycling

Visit with your lab’s purchasing department to look for ways to choose supplies with recycled content, consider the lifecycle of products purchased, and group orders to minimize shipping.

6. Minimize Air Changes

Many lab mechanical systems were designed on the premise that “the solution to pollution is dilution,” and that room air changes must be maximized to keep people safe. As an architect, my number one concern in designing a lab is providing a safe environment for its occupants, and I have found that this can often be accomplished with fewer air changes than is commonly believed. Fine-tune your supply and exhaust valves down to 6-8 air changes per hour in occupied mode, and look at setting the air changes back in unoccupied conditions. These changes can have a dramatic operational savings of more than 25%.

7. Manage Your Chemicals

If I had a nickel for every lab I’ve seen with expired or unused chemicals in it, I would be able to retire a rich man! Take frequent inventory of your chemical storerooms and research labs, and safely dispose of unneeded or expired chemicals. Check with others before ordering chemicals to avoid unnecessary duplication, and only order the appropriate quantity for the work to be completed. This saves unnecessary chemical storage space in your lab facilities, and it will make your Fire Marshall and Environmental Health and Safety officers happy!

8. Manage Plug Loads

There are many pieces of lab equipment that continue to use power when they’re plugged in but not in use. Unplugging equipment from electrical outlets, turning off the power strips when not in use or adding timer plugs to appropriate equipment are all easy solutions we rarely think of. Take stock of what is plugged in to outlets in your labs and offices, and you may even realize you never use the equipment anymore, which leads to the next solution…

9. Donate Old Lab Equipment

You can donate or redistribute scientific materials or equipment you no longer use in your lab space. When purchasing new equipment, be sure to select energy-efficient models.

10. Green Chemistry

Green chemistry is the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances. The EPA is a great source of knowledge on the principles of green chemistry and how one can implement this in their lab. Keys to this include designing your chemical syntheses to prevent waste, designing chemical products that are fully effective yet have little or no toxicity, running chemical reactions at room temperature and pressure whenever possible, and, most importantly, minimizing the potential for accidents including explosions, fires, and releases to the environment.

The institutions I work with have reported reduction to the operating costs of their labs when they implement these simple techniques, which goes to show how many opportunities there are to be greener–without having to build a LEED Platinum or Carbon Neutral facility. That said, new construction and renovation projects offer even more opportunities to address energy use and reduce environmental impact of science+technology facilities.

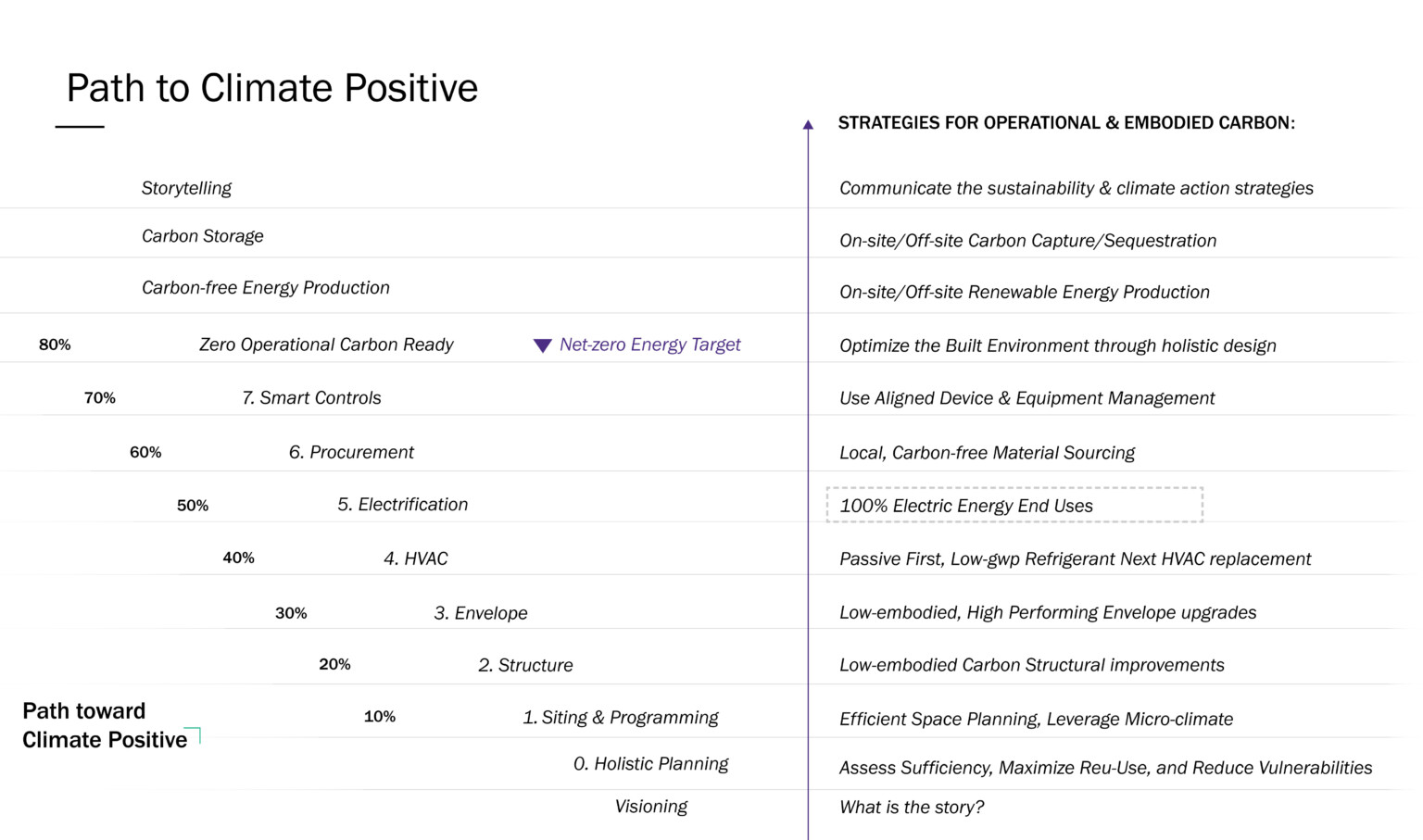

In collaboration with my colleague Prem Sundharam, Chief Climate Officer for DLR Group, I have applied the Path to Climate Positive as a strategic approach to significantly reduce greenhouse gas emissions. The Path to Climate Positive is a holistic approach to operational carbon, embodied carbon, carbon-free generation, and carbon sequestration emphasizing integrated design solutions. It follows three key principles: sufficiency, efficiency, and resiliency. The key to achieving significant impact is in balancing low-carbon design opportunities with an institutions’ large-scale renewable energy and climate action initiatives. I am always looking for other low-cost and holistic sustainable solutions that have been successfully implemented in high-performance facilities. Please feel free to share your ideas and comments with me!